Difference between revisions of "SC Hull"

Navykisysop (talk | contribs) |

(→Check list SC Hull) |

||

| (19 intermediate revisions by 3 users not shown) | |||

| Line 36: | Line 36: | ||

'''Edge margin''' 50mm | '''Edge margin''' 50mm | ||

| − | == Check list SC | + | == Check list SC Hull == |

| Line 66: | Line 66: | ||

***Indicate sightline angle | ***Indicate sightline angle | ||

***Sightline arrow direction to CL or UP | ***Sightline arrow direction to CL or UP | ||

| − | ***Bow fashion CL template to have an arrow indicating the top | + | ***Bow fashion CL template to have an arrow indicating the top - keep inside template |

| + | |||

| + | == File import and preparation before expansion == | ||

| − | |||

| − | |||

| − | |||

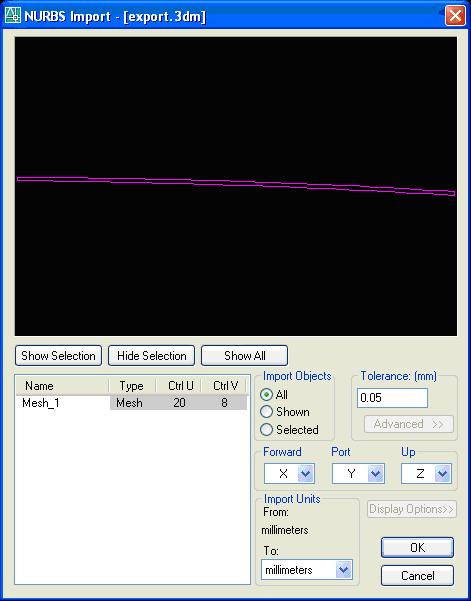

[[Image:Nurbs import.jpg]] | [[Image:Nurbs import.jpg]] | ||

| − | + | *1.Set Surface Properties: | |

| − | + | **a.Name required for templates only | |

| − | + | **b.correct Stock properties | |

| − | + | **c.correct Throw | |

| − | 1. Set Surface Properties: | + | **d.Mode ‘Solid’’ |

| − | a. Name required for templates only | + | **e.solines ‘None’ |

| − | b. correct Stock properties | + | **f.colour conform stock |

| − | c. correct Throw | + | **g.correct Markside |

| − | d. Mode ‘Solid’’ | + | *2.Create Cut Sections (settins as for Reference Lines in Structure) |

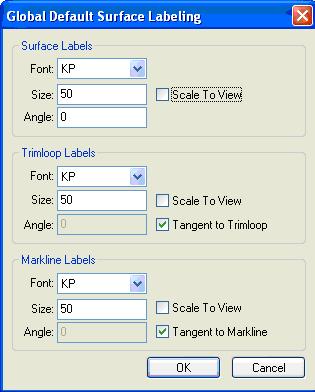

| − | e. | + | *3.Create Marklines, settings (Edit Labels): |

| − | f. colour conform stock | + | [[Image:Labeling.jpg]] |

| − | g. correct Markside | ||

| − | 2. Create Cut Sections (settins as for Reference Lines in Structure) | ||

| − | 3. Create Marklines, settings (Edit Labels): | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | [[ | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | *4.Name at least the following Marklines: | ||

| + | **a.deck at side | ||

| + | **b.tankt at side | ||

| + | *5.Split surfaces when they do not fit the stock | ||

| + | Note: do not toggle on the labels for the solids since they will appear also in the 3D solid model in the unit. | ||

| + | == Plate expansion without templates == | ||

| + | When the surface has single curvature which is not too strong, then templates are not required. | ||

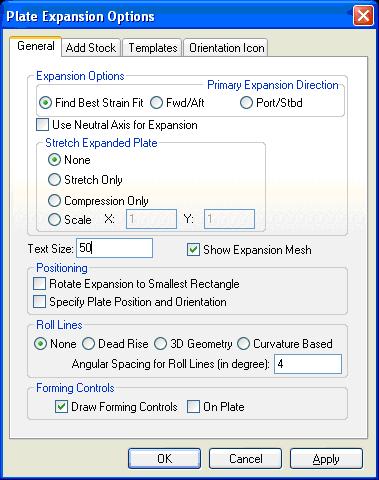

| + | *Plate Expansion Settings: | ||

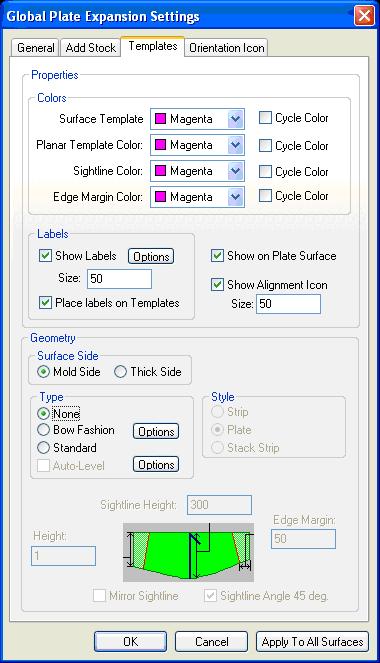

| + | [[Image:plate exp general.jpg]] [[Image:plate exp template.jpg]] [[Image:plate exp add stock.jpg]] | ||

| + | [[Image:plate exp icon.jpg]] | ||

| + | *With plate strains >1% ShipConstructor sometimes becomes inaccurate, check by measuring framelines and/or contourlines and compare them with the same lines in Rhinoceros. | ||

| + | *Toggle labels ON for Sections of the expanded surface | ||

| + | *Arrange the expanded plates for a suitable lay out in the Approval drawing. | ||

| + | == Plate expansion with standard templates == | ||

| + | When the surface has double curvature or single curvature but strong, templates are required. | ||

| + | *Templates must be concave, when the surface is convex, the Surface Side for the templates must be Thick Side instead of Mold Side. | ||

| + | *When the Surface Sside is Mold Side, the text ‘Contra Templates’ must be added to the plate and it’s templates (in CrvPlate group). | ||

| + | *Alignment icons must all indicate in the same direction within a project. | ||

| + | *Plate Expansion Settings: | ||

| + | [[Image:Plate exp standard template.jpg]] | ||

| + | '''Guidelines''' | ||

| + | *The stonger the curvature, the more templates required | ||

| + | *Use framelins for the templates as much as possible | ||

| + | *With strong curvature, the distance of the template to the end of the surface should not exceed 100mm, create additonal sections if required | ||

| + | *Names for additonal sections for templates to be ‘T01’, ‘T02’, etc. | ||

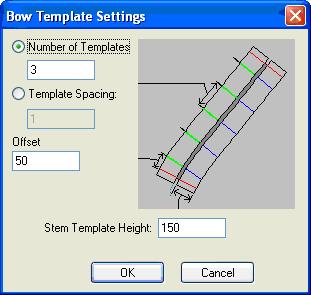

| + | == Plate expansion with bow fashion templates == | ||

| + | Use bow fashion templates for symmetrical surfaces with the neutral axis on the centerline, for example flared bows. | ||

| + | *See ‘Plate expansion with standard templates’ | ||

| + | *Plate Expansion Settings: | ||

| + | |||

| + | [[Image: bow fashion template.jpg]] | ||

| + | '''Check''' | ||

| + | *Plate and Section names are toggled ON for expanded plate | ||

| + | *Templates have Plate Name, Marking Line Name and Bracket Angle | ||

| + | *Templates are concave | ||

| + | *Alignment icon all indicate in same direction | ||

| + | *No double sightlines on plate (occur when the same plate is expanded several times) | ||

| + | *Presence of Orientation Icon | ||

| + | *Aiignment icon indicates correct side (especially with templates at Thick Side, ShipConstructor sometimes indicate wrong) | ||

| + | *Several dimensions of expanded plate, especially with a lot of curvature (framelines, contour) and see if they match in Rhino. | ||

| + | *When the strain indicates that the plate will shrink, meaning it will be too short after forming, stock must be added in the Curved Plate Group. | ||

| − | [[Category:ShipConstructor]] | + | [[Category: ShipConstructor]] |

Latest revision as of 12:03, 6 October 2009

Contents

[hide]Surfaces and expansions[edit]

How to position in the drawing

Templates[edit]

Templates are required for plates which need mechanical processing (bending or forming) to obtain the desired shape.

We need templates in the following situations:

- Single curvature (bending) with constant radius - no template required, give bending info on plate.

- Single curvature (bending) without constant radius - 1 template required.

- Double curvature (forming) - minimum 3 templates required.

Template types

- Bow Fashion - for plates which are on the center line and have symmetry around the center line (for example a bow cone)

- Standard - all other plates:

- Create the templates on the reference lines, as perpendicular to the surface as possible, or if this is not applicable:

- Use Auto-Level

Template label

- Plate Name

- Marking Line Name

- Bracket Angle

Template name is plate name + reference line name or, when using Auto-Level, plate name + T1 (T2, T3, etc.)

Template style is Plate

Edge margin 50mm

Check list SC Hull[edit]

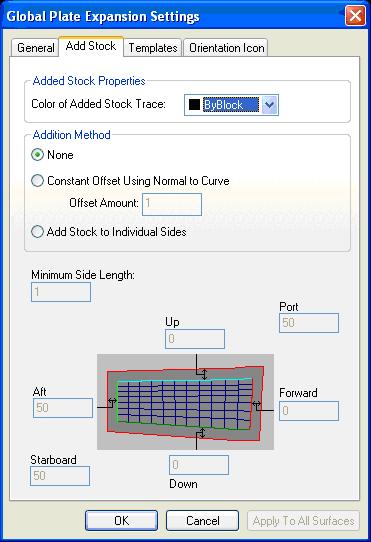

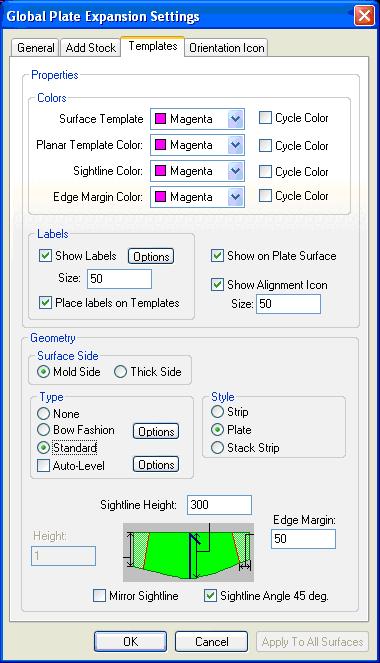

- Expansion settings

- General

- Expansion Option Find Best Strain Fit

- Stretch Expanded Plate None

- Text size 50

- Roll Lines None

- Add Stock

- None

- Templates

- Show label Plate name, Marking Line Name

- Label size 50

- Place labels on templates

- Show on Plate Surface

- Show Alignment Icon, Size 50

- Surface Side Mold Side

- Type Bow Fashion for templates with symmetry at CL, or

- Type Standard for templates with non-symmetry at CL, then

- use reference lines for templates

- use Auto-Level templates only when:

- the shape is not sufficient defined with reference lines

- the angle of the templates at the plate becomes to small

- Style Plate

- Template name is plate name + reference line name, or

- Template name is plate name + marking line name (T1, T2, etc.)

- No Edge Margin

- Indicate sightline angle

- Sightline arrow direction to CL or UP

- Bow fashion CL template to have an arrow indicating the top - keep inside template

- General

File import and preparation before expansion[edit]

- 1.Set Surface Properties:

- a.Name required for templates only

- b.correct Stock properties

- c.correct Throw

- d.Mode ‘Solid’’

- e.solines ‘None’

- f.colour conform stock

- g.correct Markside

- 2.Create Cut Sections (settins as for Reference Lines in Structure)

- 3.Create Marklines, settings (Edit Labels):

- 4.Name at least the following Marklines:

- a.deck at side

- b.tankt at side

- 5.Split surfaces when they do not fit the stock

Note: do not toggle on the labels for the solids since they will appear also in the 3D solid model in the unit.

Plate expansion without templates[edit]

When the surface has single curvature which is not too strong, then templates are not required.

- Plate Expansion Settings:

- With plate strains >1% ShipConstructor sometimes becomes inaccurate, check by measuring framelines and/or contourlines and compare them with the same lines in Rhinoceros.

- Toggle labels ON for Sections of the expanded surface

- Arrange the expanded plates for a suitable lay out in the Approval drawing.

Plate expansion with standard templates[edit]

When the surface has double curvature or single curvature but strong, templates are required.

- Templates must be concave, when the surface is convex, the Surface Side for the templates must be Thick Side instead of Mold Side.

- When the Surface Sside is Mold Side, the text ‘Contra Templates’ must be added to the plate and it’s templates (in CrvPlate group).

- Alignment icons must all indicate in the same direction within a project.

- Plate Expansion Settings:

Guidelines

- The stonger the curvature, the more templates required

- Use framelins for the templates as much as possible

- With strong curvature, the distance of the template to the end of the surface should not exceed 100mm, create additonal sections if required

- Names for additonal sections for templates to be ‘T01’, ‘T02’, etc.

Plate expansion with bow fashion templates[edit]

Use bow fashion templates for symmetrical surfaces with the neutral axis on the centerline, for example flared bows.

- See ‘Plate expansion with standard templates’

- Plate Expansion Settings:

Check

- Plate and Section names are toggled ON for expanded plate

- Templates have Plate Name, Marking Line Name and Bracket Angle

- Templates are concave

- Alignment icon all indicate in same direction

- No double sightlines on plate (occur when the same plate is expanded several times)

- Presence of Orientation Icon

- Aiignment icon indicates correct side (especially with templates at Thick Side, ShipConstructor sometimes indicate wrong)

- Several dimensions of expanded plate, especially with a lot of curvature (framelines, contour) and see if they match in Rhino.

- When the strain indicates that the plate will shrink, meaning it will be too short after forming, stock must be added in the Curved Plate Group.