Difference between revisions of "SC Manager Library"

Navykisysop (talk | contribs) (New page: == Stocks == == Materials ==) |

|||

| (30 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

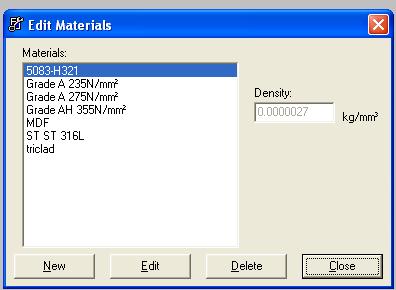

| + | == Materials == | ||

| + | |||

| + | '''Aluminium (AL)''' | ||

| + | |||

| + | *5083-H321 | ||

| + | **density 0,0000027 kg/mm3 | ||

| + | **maximum bending angle is 45° | ||

| + | |||

| + | *5083-H111 | ||

| + | **density 0,0000027 kg/mm3 | ||

| + | |||

| + | *6086-T6 - for profiles | ||

| + | **density 0,0000027 kg/mm3 | ||

| + | |||

| + | |||

| + | '''Stainless steel (SST)''' | ||

| + | |||

| + | *316L | ||

| + | **density 0,00000795 kg/mm3 | ||

| + | |||

| + | |||

| + | '''Steel (ST)''' | ||

| + | |||

| + | *Grade A 235 N/mm2 | ||

| + | **density 0,0000078 kg/mm3 | ||

| + | *Grade A 275 N/mm2 | ||

| + | **density 0,0000078 kg/mm3 | ||

| + | *Grade AH 355 N/mm2 | ||

| + | **density 0,0000078 kg/mm3 | ||

| + | |||

| + | |||

| + | '''Triclad (TC)''' | ||

| + | |||

| + | TRICLAD® is the trade name of Merrem & la Porte for aluminium/steel transition joints. In generic terms the product is usually referred to as structural transition joint (STJ). It's cross section consist of an explosion bonded composite of seawater resistant aluminium alloy and C-steel and is usually applied in the form of strips or pads when welding together aluminium and steel structures in ship-and off shore construction. | ||

| + | |||

| + | '''Detaclad''' | ||

| + | |||

| + | Is a similar product from DMC (Dynamic Materials Corperation).See Triclad.. | ||

| + | |||

| + | ''Construction guidelines'' | ||

| + | [[Media:H:\Home\Materials\Metal\Tricald.pdf]] | ||

| + | |||

| + | ''Availability'' | ||

| + | Standard strip length 3800 mm. | ||

| + | Strip (plate) height is 34mm. | ||

| + | Minimum strip width 10 mm, commonly used strip width is 24mm. | ||

| + | |||

| + | ''External links'' | ||

| + | *[http://www.triclad.com Triclad corporate website] | ||

| + | |||

| + | '''MDF''' | ||

| + | |||

| + | *density 0 kg/mm3 | ||

| + | *thickness is 6mm used for templates | ||

| + | |||

| + | [[Image:Materials.jpg]] | ||

== Stocks == | == Stocks == | ||

| + | Sheet sizes '''steel''' and '''aluminium''': | ||

| + | |||

| + | ''Standard'' | ||

| + | |||

| + | *2000x6000 | ||

| + | '' | ||

| + | Standard 1'' | ||

| + | *1250x2500 | ||

| + | *1500x3000 | ||

| + | *1500x6000 | ||

| + | *2000x1000 | ||

| + | *2000x2000 | ||

| + | *2000x4000 | ||

| + | |||

| + | ''Standard 2'' | ||

| + | |||

| + | *2000x8000 (small price difference) | ||

| + | *2000x10000 | ||

| + | *2500x6000 (small price difference) | ||

| + | *2500x8000 | ||

| + | *3000x6000 | ||

| + | *3000x8000 | ||

| + | *…….x10000 | ||

| + | *…….x12000 | ||

| + | |||

| + | |||

| + | MDF06 | ||

| + | *2440x1220 | ||

| + | *3050x1220 | ||

| + | |||

| + | |||

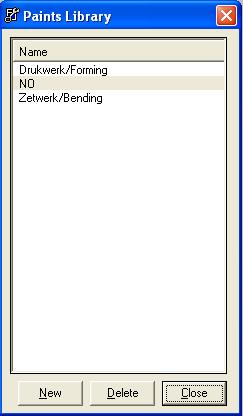

| + | == Finishes/Paint == | ||

| + | |||

| + | |||

| + | '''Bending/Zetwerk''' | ||

| + | |||

| + | Is the process of transforming a flat sheet in to a '''single''' curved sheet. | ||

| + | *constant radius - bending info on plate indicates the required shape | ||

| + | *non constant radius - 1 or 2 templates indicate the required shape | ||

| + | ''Restrictions'' | ||

| + | |||

| + | Aluminum 5083-H321 can be bend to an angle of 45° maximum. | ||

| − | == | + | '''Forming/Drukwerk''' |

| + | |||

| + | Is the process of transforming a flat sheet in to a '''double''' curved sheet (compound curvature). | ||

| + | The required shape is indicated by 3 or more templates. | ||

| + | |||

| + | [[Image:Finishes.jpg]] | ||

| + | |||

| + | |||

| + | == CNC machines == | ||

| + | |||

| + | The machines which cut the parts from the nest plates. | ||

| + | |||

| + | #NC machine for aluminum is : BURNY-phantom | ||

| + | #NC machine for steel is : Snijtech-staal | ||

| + | |||

| + | The settings in manager for both machines are: | ||

| + | *Pierce time:5 seconds | ||

| + | *Cut feed - 4000 | ||

| + | *Mark feed - 17000 | ||

| + | *fast feed - 20000 | ||

| + | |||

| + | These are average times for all thicknesses | ||

| + | |||

| + | == Piping == | ||

| + | |||

| + | '''Stock catalog''' | ||

| + | |||

| + | |||

| + | [[Category: ShipConstructor]] | ||

Latest revision as of 11:50, 26 September 2013

Contents

[hide]Materials[edit]

Aluminium (AL)

- 5083-H321

- density 0,0000027 kg/mm3

- maximum bending angle is 45°

- 5083-H111

- density 0,0000027 kg/mm3

- 6086-T6 - for profiles

- density 0,0000027 kg/mm3

Stainless steel (SST)

- 316L

- density 0,00000795 kg/mm3

Steel (ST)

- Grade A 235 N/mm2

- density 0,0000078 kg/mm3

- Grade A 275 N/mm2

- density 0,0000078 kg/mm3

- Grade AH 355 N/mm2

- density 0,0000078 kg/mm3

Triclad (TC)

TRICLAD® is the trade name of Merrem & la Porte for aluminium/steel transition joints. In generic terms the product is usually referred to as structural transition joint (STJ). It's cross section consist of an explosion bonded composite of seawater resistant aluminium alloy and C-steel and is usually applied in the form of strips or pads when welding together aluminium and steel structures in ship-and off shore construction.

Detaclad

Is a similar product from DMC (Dynamic Materials Corperation).See Triclad..

Construction guidelines Media:H:\Home\Materials\Metal\Tricald.pdf

Availability Standard strip length 3800 mm. Strip (plate) height is 34mm. Minimum strip width 10 mm, commonly used strip width is 24mm.

External links

MDF

- density 0 kg/mm3

- thickness is 6mm used for templates

Stocks[edit]

Sheet sizes steel and aluminium:

Standard

- 2000x6000

Standard 1

- 1250x2500

- 1500x3000

- 1500x6000

- 2000x1000

- 2000x2000

- 2000x4000

Standard 2

- 2000x8000 (small price difference)

- 2000x10000

- 2500x6000 (small price difference)

- 2500x8000

- 3000x6000

- 3000x8000

- …….x10000

- …….x12000

MDF06

- 2440x1220

- 3050x1220

Finishes/Paint[edit]

Bending/Zetwerk

Is the process of transforming a flat sheet in to a single curved sheet.

- constant radius - bending info on plate indicates the required shape

- non constant radius - 1 or 2 templates indicate the required shape

Restrictions

Aluminum 5083-H321 can be bend to an angle of 45° maximum.

Forming/Drukwerk

Is the process of transforming a flat sheet in to a double curved sheet (compound curvature). The required shape is indicated by 3 or more templates.

CNC machines[edit]

The machines which cut the parts from the nest plates.

- NC machine for aluminum is : BURNY-phantom

- NC machine for steel is : Snijtech-staal

The settings in manager for both machines are:

- Pierce time:5 seconds

- Cut feed - 4000

- Mark feed - 17000

- fast feed - 20000

These are average times for all thicknesses

Piping[edit]

Stock catalog