Difference between revisions of "SC Hull"

From NavykI

Navykisysop (talk | contribs) |

Navykisysop (talk | contribs) |

||

| Line 102: | Line 102: | ||

[[Image:plate exp icon.jpg]] | [[Image:plate exp icon.jpg]] | ||

| + | |||

| + | *With plate strains >1% ShipConstructor sometimes becomes inaccurate, check by measuring framelines and/or contourlines and compare them with the same lines in Rhinoceros. | ||

| + | *Toggle labels ON for Sections of the expanded surface | ||

| + | *Arrange the expanded plates for a suitable lay out in the Approval drawing. | ||

| + | |||

| + | == PLATE EXPANSION WITH STANDARD TEMPLATES == | ||

| + | |||

| + | When the surface has double curvature or single curvature but strong, templates are required. | ||

| + | |||

| + | **Templates must be concave, when the surface is convex, the Surface Side for the templates must be Thick Side instead of Mold Side. | ||

| + | **When the Surface Sside is Mold Side, the text ‘Contra Templates’ must be added to the plate and it’s templates (in CrvPlate group). | ||

| + | **Alignment icons must all indicate in the same direction within a project. | ||

| + | **Plate Expansion Ssettings: | ||

| + | |||

| + | [[Image:Plate exp standard template.jpg]] | ||

| + | |||

| + | '''Guidelines''' | ||

| + | |||

| + | **The stonger the curvature, the more templates required | ||

| + | **Use framelins for the templates as much as possible | ||

| + | **With strong curvature, the distance of the template to the end of the surface should not exceed 100mm, create additonal sections if required | ||

| + | **Names for additonal sections for templates to be ‘T01’, ‘T02’, etc. | ||

| + | |||

Revision as of 13:52, 4 June 2009

Contents

[hide]Surfaces and expansions

How to position in the drawing

Templates

Templates are required for plates which need mechanical processing (bending or forming) to obtain the desired shape.

We need templates in the following situations:

- Single curvature (bending) with constant radius - no template required, give bending info on plate.

- Single curvature (bending) without constant radius - 1 template required.

- Double curvature (forming) - minimum 3 templates required.

Template types

- Bow Fashion - for plates which are on the center line and have symmetry around the center line (for example a bow cone)

- Standard - all other plates:

- Create the templates on the reference lines, as perpendicular to the surface as possible, or if this is not applicable:

- Use Auto-Level

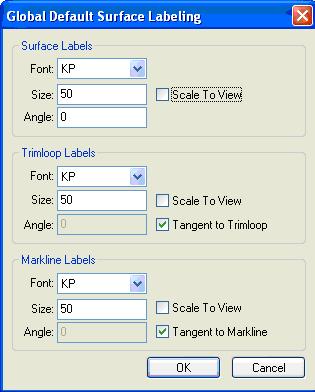

Template label

- Plate Name

- Marking Line Name

- Bracket Angle

Template name is plate name + reference line name or, when using Auto-Level, plate name + T1 (T2, T3, etc.)

Template style is Plate

Edge margin 50mm

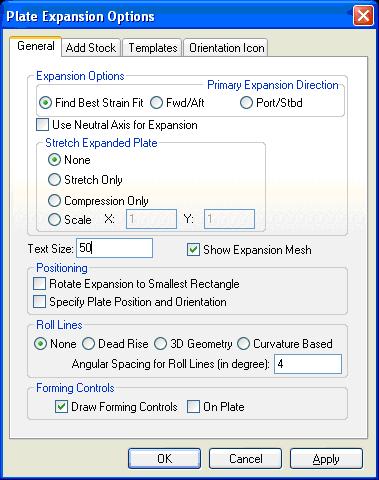

Check list SC HULL

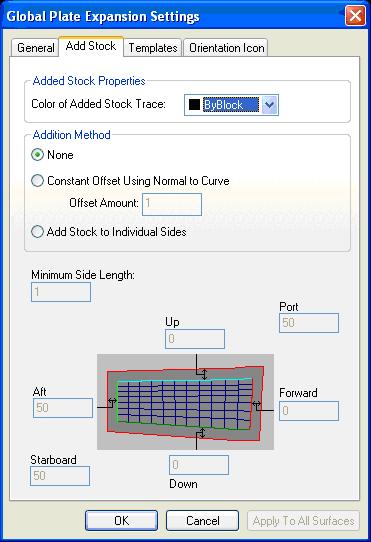

- Expansion settings

- General

- Expansion Option Find Best Strain Fit

- Stretch Expanded Plate None

- Text size 50

- Roll Lines None

- Add Stock

- None

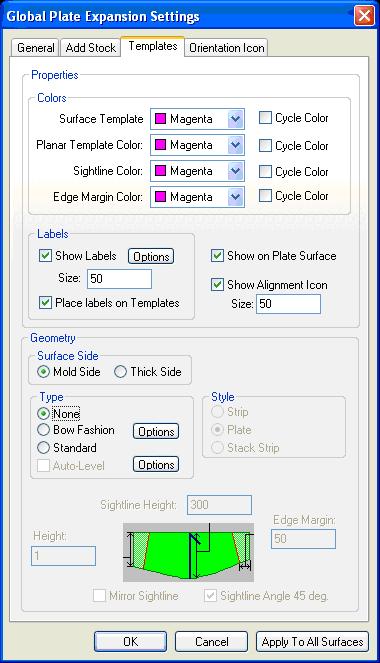

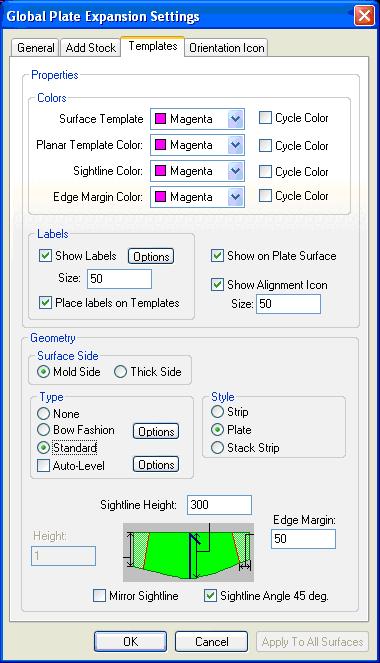

- Templates

- Show label Plate name, Marking Line Name

- Label size 50

- Place labels on templates

- Show on Plate Surface

- Show Alignment Icon, Size 50

- Surface Side Mold Side

- Type Bow Fashion for templates with symmetry at CL, or

- Type Standard for templates with non-symmetry at CL, then

- use reference lines for templates

- use Auto-Level templates only when:

- the shape is not sufficient defined with reference lines

- the angle of the templates at the plate becomes to small

- Style Plate

- Template name is plate name + reference line name, or

- Template name is plate name + marking line name (T1, T2, etc.)

- No Edge Margin

- Indicate sightline angle

- Sightline arrow direction to CL or UP

- Bow fashion CL template to have an arrow indicating the top

- General

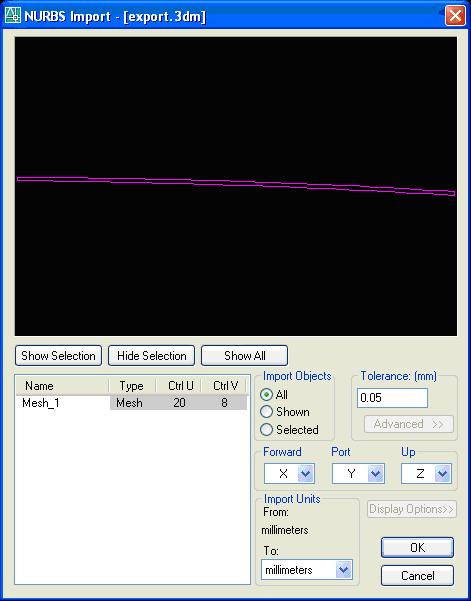

FILE IMPORT + PREPARATIONS BEFORE EXPANSION

- 1.Set Surface Properties:

- a.Name required for templates only

- b.correct Stock properties

- c.correct Throw

- d.Mode ‘Solid’’

- e.solines ‘None’

- f.colour conform stock

- g.correct Markside

- 2.Create Cut Sections (settins as for Reference Lines in Structure)

- 3.Create Marklines, settings (Edit Labels):

- 4.Name at least the following Marklines:

- a.deck at side

- b.tankt at side

- 5.Split surfaces when they do not fit the stock

Note: do not toggle on the labels for the solids since they will appear also in the 3D solid model in the unit.

PLATE EXPANSION WITHOUT TEMPLATES

- When the surface has single curvature which is not too strong, then templates are not required.

- Plate Expansion Settings:

- With plate strains >1% ShipConstructor sometimes becomes inaccurate, check by measuring framelines and/or contourlines and compare them with the same lines in Rhinoceros.

- Toggle labels ON for Sections of the expanded surface

- Arrange the expanded plates for a suitable lay out in the Approval drawing.

PLATE EXPANSION WITH STANDARD TEMPLATES

When the surface has double curvature or single curvature but strong, templates are required.

- Templates must be concave, when the surface is convex, the Surface Side for the templates must be Thick Side instead of Mold Side.

- When the Surface Sside is Mold Side, the text ‘Contra Templates’ must be added to the plate and it’s templates (in CrvPlate group).

- Alignment icons must all indicate in the same direction within a project.

- Plate Expansion Ssettings:

Guidelines

- The stonger the curvature, the more templates required

- Use framelins for the templates as much as possible

- With strong curvature, the distance of the template to the end of the surface should not exceed 100mm, create additonal sections if required

- Names for additonal sections for templates to be ‘T01’, ‘T02’, etc.