General applicable rules

Contents

[hide]Rules for viewing the structure

- Frames - always look from AFT to FORWARD. The structure in FWD is marked dashed.

- Longitudinals- always look form STARBOARD to PORTSIDE. The structure in PORT is marked dashed.

- Decks- always look from TOP to Down.The structure under deck is marked dashed.

In planar group properties the 'default mark side is:

- AFT for frames

- STB for longitudinals

- DOWN for decks

In every project you have to search for the sign where the thickness of frames is changing form Aft to Forward.

Solid Colors

- Green - outside cut

- Yellow - inside cut

- Cyan - continuous or dached - marking line

- Grey - no process (only text is part of plate parts).The other Grey entities except parts must be on 'No_Process' layer.

| MDF | ' | ' |

| Thickness | Autocad Code | RGB |

| 6 | 34 | 153.76.0 |

| 9 | 190 | 127.0.255 |

| 25 | 36 | 127.63.0 |

| Aluminium 5083-H321/5086 | ' | ' |

| Thickness | Autocad Code | RGB |

| 1 | 11 | 255.127.127 |

| 1.5 | 215 | 153.76.153 |

| 2 | 2 | 255.255.0 |

| 2.5 | 52 | 204.204.0 |

| 3 | 3 | 0.255.0 |

| 4 | 4 | 0.255.255 |

| 5 | 5 | 0.0.255 |

| 6 | 6 | 255.0.255 |

| 7 | 254 | 214.214.214 |

| 8 | 224 | 153.0.114 |

| 9 | 29 | 76.47.38 |

| 10 | 10 | 255.0.0 |

| 12 | 112 | 0.204.102 |

| 15 | 13 | 204.102.102 |

| 18 | 18 | 76.0.0 |

| 20 | 20 | 255.63.0 |

| 25 | 125 | 76.153.133 |

| 30 | 30 | 255.127.0 |

| 35 | 31 | 255.191.127 |

| 40 | 40 | 255.191.0 |

| 50 | 150 | 0.127.255 |

| 60 | 200 | 191.0.255 |

| 80 | 82 | 51.204.0 |

| Aluminium H111 | ' | ' |

| Thickness | Autocad Code | RGB |

| 3 | 70 | 127.255.0 |

| 4 | 132 | 0.204.204 |

| 5 | 160 | 0.63.255 |

| 6 | 230 | 255.0.127 |

| 7 | 252 | 132.132.132 |

| 8 | 226 | 127.0.95 |

| 10 | 14 | 153.0.0 |

| 12 | 115 | 76.153.114 |

| 15 | 15 | 153.76.76 |

| 20 | 22 | 204.51.0 |

| 30 | 32 | 204.102.0 |

| 40 | 42 | 204.153.0 |

| 80 | 84 | 38.153.0 |

| Triclad | ' | ' |

| Thickness | Autocad Code | RGB |

| All | 60 | 191.255.0 |

| Steel Gr. A | ' | ' |

| Thickness | Autocad Code | RGB |

| 1.5 | 195 | 114.76.153 |

| 2 | 220 | 255.0.191 |

| 2.5 | 250 | 51.51.51 |

| 3 | 63 | 178.204.102 |

| 4 | 134 | 0.153.153 |

| 5 | 165 | 76.95.153 |

| 6 | 235 | 153.76.114 |

| 7 | 9 | 192.192.192 |

| 8 | 227 | 127.63.111 |

| 9 | 219 | 76.38.76 |

| 10 | 16 | 127.0.0 |

| 11 | 211 | 255.127.255 |

| 12 | 117 | 63.127.95 |

| 13 | 243 | 204.102.127 |

| 15 | 17 | 127.63.63 |

| 20 | 24 | 153.38.0 |

| 25 | 25 | 153.95.76 |

| 30 | 34 | 153.76.0 |

| 40 | 44 | 153.114.0 |

| 50 | 54 | 153.153.0 |

| 80 | 86 | 31.127.0 |

| Stainless Steel 304/316/316L | ' | ' |

| Thickness | Autocad Code | RGB |

| 3 | 62 | 153.204.0 |

| 4 | 136 | 0.127.127 |

| 5 | 168 | 0.19.76 |

| 6 | 237 | 127.63.95 |

| 7 | 251 | 91.91.91 |

| 8 | 228 | 76.0.57 |

| 10 | 18 | 76.0.0 |

| 12 | 119 | 38.76.57 |

| 15 | 19 | 76.38.38 |

| 20 | 26 | 127.31.0 |

| 30 | 36 | 127.63.0 |

| 40 | 46 | 127.95.0 |

| 80 | 88 | 19.76.0 |

Planar groups

The start of every project is creating planar groups using Rhino sections for frames, longitudinals and decks. Before you create the planar group you must know the plate thickness so you can set up it in planar group properties.

In every planar group after creation you must follow the below procedure:

- Insert Rhino section

- SC Utilities/Remove vertices below tolerance: 0.05

- UCS must be on construction - check by click on the Activate UCS button.

- SC Utilities/3D to 2D

- Copy rhino section to revision layer; if revision has already a section than give it a color first so you can see the difference with the new one.

- Check the Rhino section if is correct.If you have doubts about the double lines, discontinuities, check it with the Rhino model and bring section again.

- check the units,text style,dimension style, line type scale before starting modeling the planar group.If are not OK make the correct settings.

- Add the base lines or Central line using tool palette or replicate from an existing planar group.

- Limit the area where you have to draw.For decks and LG let 250mm from frame line in no process.

When you start to create the part the steps are:

- Add offsets for plate thickness for the adjacent structure

- Use mark group intersection in order to see the relation with the rest of structure.Here you must check if the offsets are OK.

- Study the structure and the dwg and search for similar situation in order to define the plate contour.

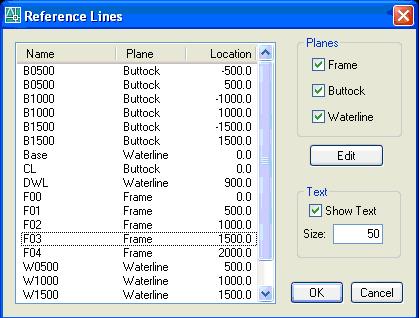

- Add reference lines

- Add plate thikness

- Mlink model in order to see what other connection structure must be marked.

- Take care of marking rules for continuing and dashed.

- Check 3d model to see if the elements connect good.

- Check if all entities are on the correct layer.

- Purge planer group.

Piecemark

- Size: 40mm

- When the piecemark does not fit on the part then decrease the size in steps of 5mm

- In the approval drawing indicate piecemarks with a leader for:

- scale 1:20 - piecemarks smaller than 30mm

- scale 1:25 - piecemarks smaller than 35mm

If you need to delete a defined part (a block with piecemark which is added to the project database) than DO NOT USE DELETE but UNDEFINE which is a ShipConstrutor tool. If you need to modify a defined part than you can choose for one of methods below:

- Undefine the part with keeping the autocad entities and than define it again. Is used when you need to modify the solid also.

- Deactivate the part, modify it and reactivate it again. Is used when you do not need to modify the solid.

Planar group

- Look for watertight bulkheads and tank plates, these are without scallops.

- Start drawing the continueing construction. This means the parts of the construction which continue when passing other planar groups. Finish the planar group completely with profile solids (even if they are not in the scope of delivery). The reason is that you can use the intersections in the not-continueing planar groups.

- When creating a new planar group take use the correct thickness and thickness throw. This is imortant for marking group intersections. When you finish a planar group, check the 3D model with the intersecting/connecting planar groups for possible irregularities.

- When a planar group is intersected with a skewed group, then make the skewed group first to have the correct intersection markings.

- Connecting construction fully detailed in no process for all frames and centerline, linetype continuous for near side, dashed for far side

- Draw connecting sections to show how construction continues

- Replicate

Parts

- For every import remove vertices below 0.05mm

- Close outside and inside contours

- Split part if it is bigger than the sheet size, conform the following rules:

- Shortest welding line

- Parallel to a reference line, at intervals of 50mm

- Minimum 50mm distance to adjacent construction

- Show reference lines, every part has to have at least 1 reference line

- Mark all interfering construction (plates, stiffeners)

- Show thickness

- All marking lines and No process entities to be within part borders

- If applicable show:

- Orientation icon

- Contra templates’

- Group together:

- Piecemark

- (Orientation icon)

- (‘Contra templates’)

- Text and piecemarks which do not fit within the part borders to be incremental decreased with 5

- Inside cut:

- Holes smaller than Ø50 are marked instead of cut

- Cuts <6mm to be marked (palsma cut is 6mm minimum)

- No process:

- text only

- Not to interfere with markinglines

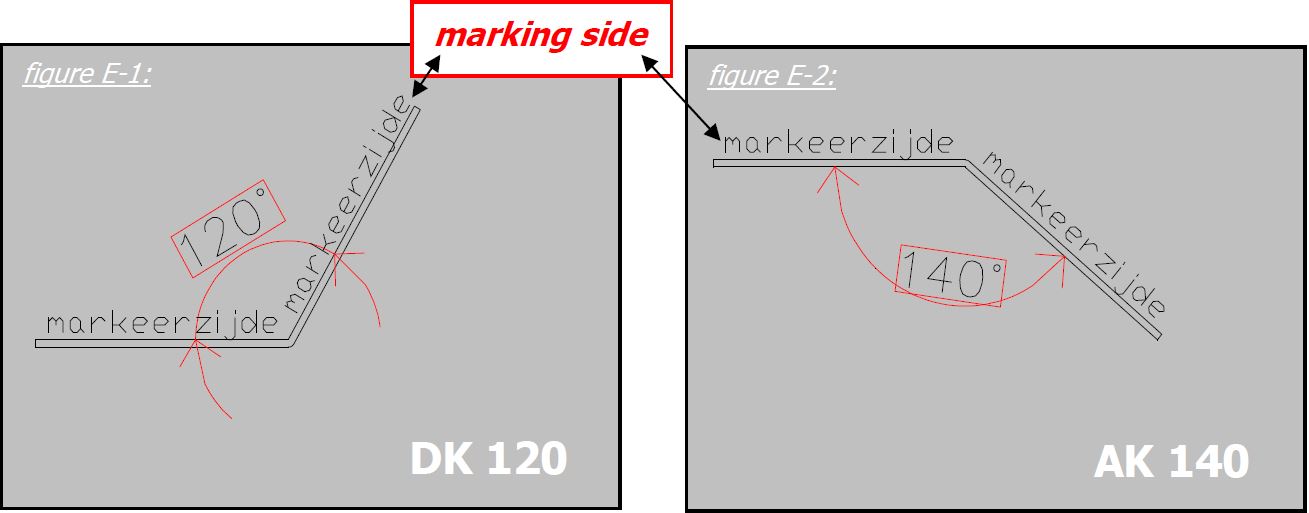

- Bending parts:

- Maximum bending length is 4000mm (machine limiet)

- Bending requires at least 50mm plate next to the bending line, if the bending stops at the plate edge, add 50mm stock

- Always mark the plate at the side where the bending goes to (this side), ‘other side’ only to be used for exceptions

- Flange: indicate with bending line and diamonds, text example: FL50 90°TS

- Knuckle: indicate bending line, text example: KN 45°TS

- Radius: Indicate begin and end of bending with a line

- Draw an arrow from begin line to end line and inidicate:

- Knuckle/Radius

- Angle

- Bending direction ‘this side’ (‘TS’ or in Dutch ‘DZ’) or ‘other side’ (‘OS’ or in Dutch ‘AZ’)

- When creating the part select ‘Bending’ in the Paint menu.

- Radius: Indicate begin and end of bending with a line

- Welding bevel:

- when indicated on the plate, it is done for all sides

- Indicate:

- bevel in degrees or ‘NO BEVEL’ for 0 degrees

- side ‘this side’ (‘TS’ or in Dutch ‘DZ’) or ‘other side’ (‘OS’ or in Dutch ‘AZ’)

- example ‘BEVEL 30 TS’

- Stock is indicated with a + and the amount example ‘+50’

- Long narrow parts with curvature – mark straight sightline

- Sightlines

- Add to long narrow parts which migh deform during construction(build T-profiles, etc.)

Standard parts

- For every part appearing ≥5 times.

Reference lines

- Origins are centerline and baseline.

- Spacing is standard 500mm

- F frame 2 digits

- B buttock 4 digits

- W waterline 4 digits

- Layers/colors:

- Lines _PRD marking

- Text _PRD no process

- Text height 50

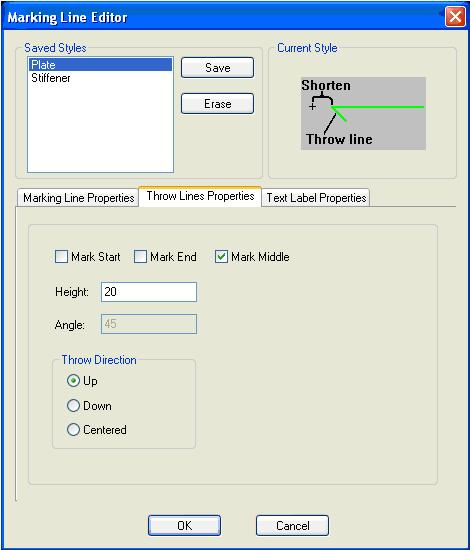

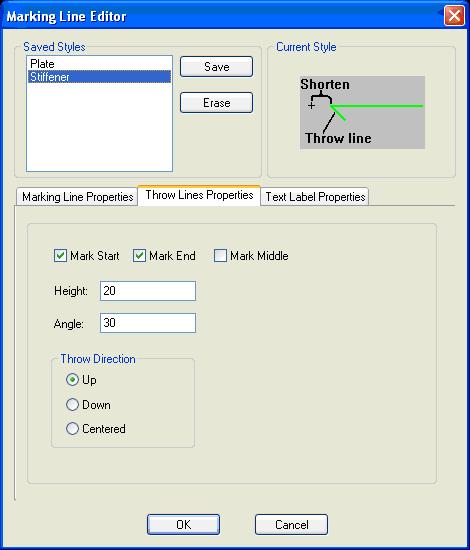

Marking lines

- Plates are marked with a marking line at the CL and a double bubble

- Profiles are marked with a marking line at the CL and end markings at both ends

- Continuous line when on near side, dashed when on far side

- Holes are marked as the following:

- < Ø20 marked with cross

- Ø 20-50 marked contour + cross

- > Ø50 inside contour (cut)

Orientation icon

- In every curved plate

- In every part which is hard to identify from it’s shape

- Use only:

- FWD forward

- UP up

- CL centerline